Café Closure

19th July 2025

Due to staff holidays

& illness the museum café will be closed on

Saturday 19th July.

The museum will be open as normal

Apologies for any

inconvenience.

The café will be open again as normal from

Thursday 24th July

CIMA Café Team

Calderdale Industrial Museum’s Full Steam Ahead Appeal

Here at Calderdale Industrial Museum we are working to bring life back to our beautiful steam engines and we are seeking to raise funds to complete this exciting steam project. These engines include the early beam engine, the vertical steam engine, the Newton Bean and Mitchell horizontal engine and the Belliss & Morcom twin cylinder steam generator set. Using steam to power these engines again will add a fantastic dimension to the visitor experience at the museum.

The museum has been lucky to have some very generous support from individuals who have donated a considerable amount of money to help fund this, but we are now looking to widen the Appeal, as we still need to raise more money. With the launch of the Full Steam Ahead Appeal we hope to raise the final amount of funding to complete the project, which will allow us to complete the task of refurbishing the engines, install a smaller, more efficient boiler and carry out the necessary safety and operation training.

We have continued to seek funds to complete the project but have now officially launched the Appeal into the public domain. We have been making use of our lovely Baby Enid collection model, made for us by Tony Griffiths, which you will see in the Power Gallery or maybe in the yard on a warm dry day. A press release has been sent to the major local newspapers and specialist publications. It is hoped that this will encourage further donations to allow us to reach our target.

If you would like to support the Appeal by donating, you can do this at the museum in person or on the website on our donation page or you can contact the museum at manager (at) calderdaleindustrial (dot) co (dot) uk

Bringing steam back to the power gallery will be integral to showing how these amazing steam engines drove the development of the Industrial Revolution in this area. Visitors will be able to see how these magnificent workhorses powered the industry of Calderdale, and many could even enjoy specialist experiences and steam days, which will bring enthusiasts from around the country to this vibrant area of West Yorkshire. The introduction of steam to the museum should make a significant addition to the overall visitor experience, further cementing the museum’s place as a major contributor to local heritage and the economy and driving their efforts to reach a wider audience.

Museum wins award from Tripadvisor

Calderdale Industrial Museum is pleased to announce today that it has been recognized in Tripadvisor’s® Travellers’ Choice® Awards for 2024. The award honours businesses that consistently earn great reviews, placing them among the top 10% of listings around the world on Tripadvisor.

Donations – Making a Donation to Calderdale Industrial Museum

Some of the hardworking members of the Collections team

Are you thinking of making a donation of an item to Calderdale Industrial Museum? Donations help us to enlarge our collection, which already holds many objects given by the public.

All donations must comply with our Collections Policy. They’ll need to have a local industrial connection, be in good enough condition for display and not duplicate anything we already have. Please don’t be offended if we can’t accept your donation. It may be too big, duplicate what we have, or not have local relevance. If this is the case we’ll try to suggest where else it might be of more interest.

We are only interested in technical text books or histories of local companies, so for other books we recommend you contact Halifax Central Library on Square Road, Halifax, and for paper records West Yorkshire Archive Service as we don’t hold archive material.

Please don’t leave any objects with our staff.

If a member of Collections Team isn’t available, please leave your contact details, and information about the item(s) and preferably with a photograph of it, with our reception, or better still either email this information to the museum using the website contact form, or write to us at – Calderdale Industrial Museum, Square Road, Halifax HX1 1QG – along with any images and details you have of the object.

All offers of donations are discussed at our Collections Meetings, after which we will get back to you with an answer. Please remember we are all volunteers and only work part time so this may not be straight away.

Thank you again for considering Calderdale Industrial Museum.

Enquiries

We are also happy to answer questions about our collections, exhibitions and displays, but we are a small team and may not be able to answer straight away. If you have any queries that our volunteers can’t answer there and then please feel free to email or write to us as detailed above.

‘Come and Have A Go’ on the Top Floor!

Halifax Charity Gala

Half-term fun at the museum – Prize winner !

Congratulations to Oliver Sloane, the lucky prize winner of our “What’s this?” half-term quiz at the museum. He used his detective skills to correctly identify the exhibits in the museum from photos that had been taken from unusual angles. If you are planning on visiting the museum, don’t worry, we always have a quiz running for our younger visitors.

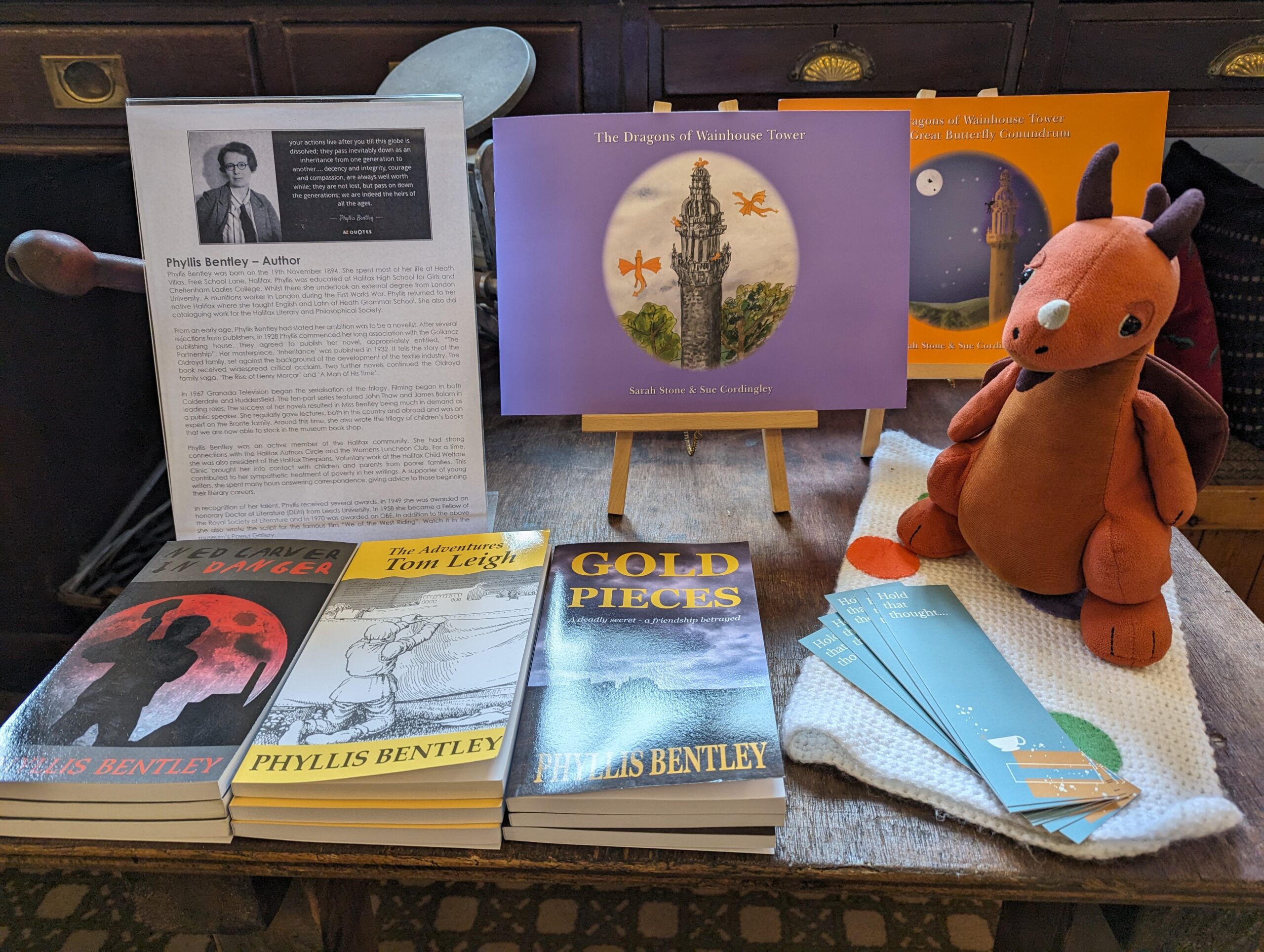

Children’s books

Halifax Gift Card

Calderdale Industrial Museum is pleased to announce that you can now use your Halifax Gift Card in the museum. You can pay your admission fee with it, or use it in the shop or cafe. The cards can be bought at Tourist Information Centres and can be used at a huge range of places. You can find out more about the card HERE.

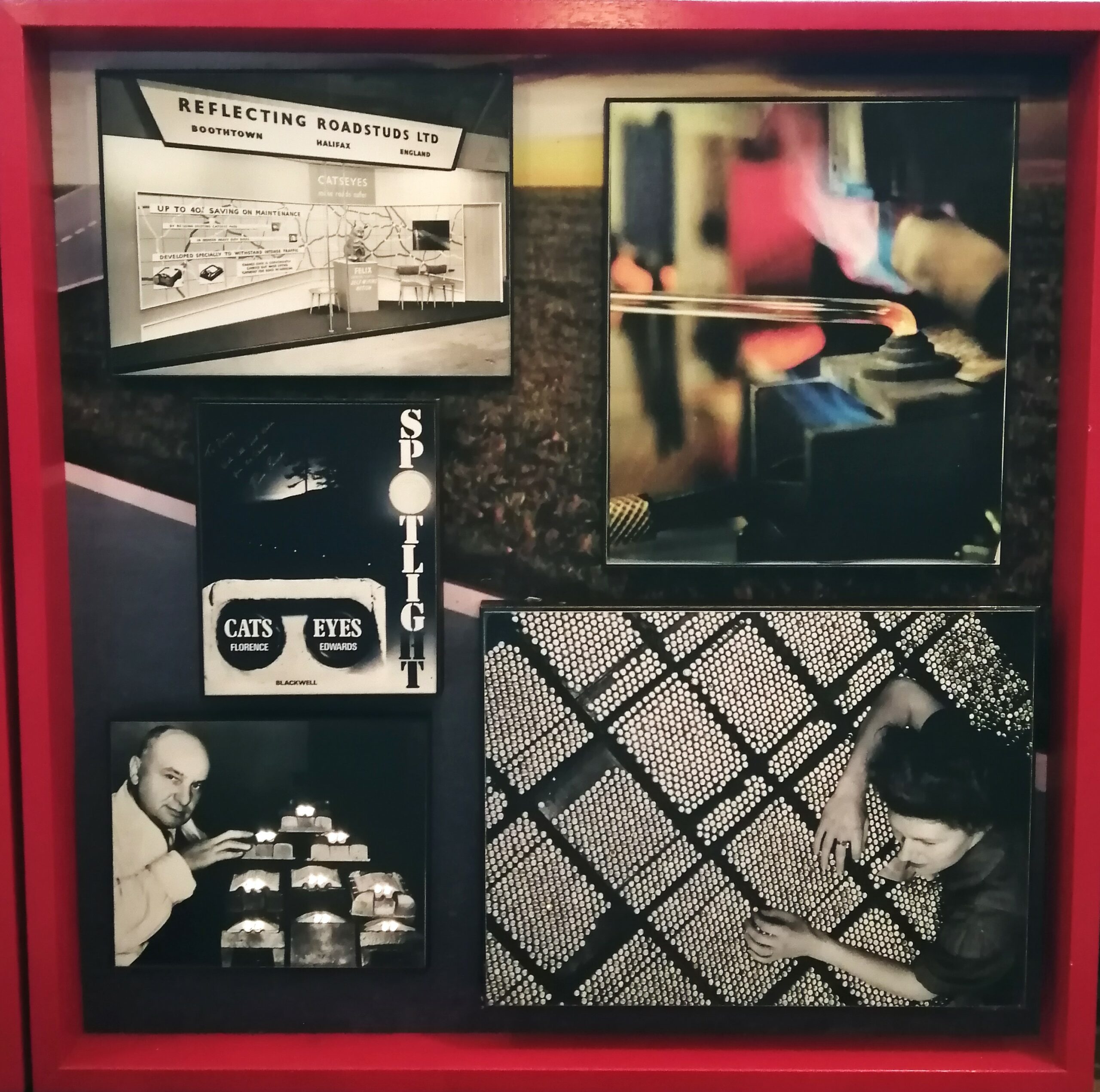

Percy Shaw’s Catseyes

Calderdale Industrial Museum is delighted to have received the generous donation from Glenda Shaw of several display panels from the former pub “The Percy Shaw” in Halifax. They will form part of our plans to revamp the catseyes dispay in the museum. For those of you who don’t know, in 1934, the late Percy Shaw almost crashed while driving home from the pub on a foggy night. He was saved when his headlights were reflected in the eyes of a cat and it gave him a brilliant idea. He invented reflective studs for the road and called them catseyes. Come and find out even more about this Halifax inventor, and all the other local inventions and industries in Calderdale at the museum.

More new ceramics in the museum shop

More new ceramics in the museum shop

We are delighted that here at Calderdale Industrial Museum we are able to bring you the beautiful, yet functional ceramics from local potter Anne Cahill in our shop. Anne is based in Calderdale, currently at Brier Hey Studios in Mytholmroyd. Her work is largely functional and wheel-thrown. She mixes her own glazes and fires to stoneware temperatures using wood, gas or an electric kiln.

Volunteers needed!

We are currently recruiting volunteers for Calderdale Industrial Museum. We need volunteers to work in a wide range of roles. These include weekend guides to show visitors around, volunteers to help in the cafe and on reception, volunteers to help maintain and restore our exhibits, researchers to find out more about our collection and volunteers who can help with marketing, school visits and exhibitions.

We are currently recruiting volunteers for Calderdale Industrial Museum. We need volunteers to work in a wide range of roles. These include weekend guides to show visitors around, volunteers to help in the cafe and on reception, volunteers to help maintain and restore our exhibits, researchers to find out more about our collection and volunteers who can help with marketing, school visits and exhibitions.

You will be part of a great team if you join us. We hold regular social events, including trips and talks. No two days are ever the same!

We are also recruiting for the key Board-level position of Business Development Specialist. Apply your business development expertise to help us achieve our objectives of becoming a major regional and national heritage centre, and a valued local community asset. Click on the link below to apply. https://reachvolunteering.org.uk/opp/board-level-business-development-specialist

New ceramics and weavings in the museum shop

3D scanning technology workshop

Some of the wonderful volunteers at Calderdale Industrial Museum were treated to a fascinating workshop on 3D scanning technology today run Yuan Gao. Yuan is PhD student at Leeds University and is carrying out research on the role of sound in online museums, and wants to produce 3D models and audio recordings of industrial machines.

Some of the wonderful volunteers at Calderdale Industrial Museum were treated to a fascinating workshop on 3D scanning technology today run Yuan Gao. Yuan is PhD student at Leeds University and is carrying out research on the role of sound in online museums, and wants to produce 3D models and audio recordings of industrial machines.

The museum has been working with Yuan and hopes to include her 3D models and sound materials on our website. The museum and it’s volunteers are definitely aiming to keep up to date with 21st century technology!

Here are some of our amazing volunteers being taught how to make socks on our sock knitting machines by our experts !

Moquette and Wilton loom update – July 2023

We are very pleased to announce that the amazing moquette loom in the museum is now fully operational and is weaving again after our volunteer Keith’s hard work. We are also very excited that another of our looms, the Wilton carpet loom is almost operational again. David, another of our fabulous volunteers has been getting the loom ready to weave again.

We are very pleased to announce that the amazing moquette loom in the museum is now fully operational and is weaving again after our volunteer Keith’s hard work. We are also very excited that another of our looms, the Wilton carpet loom is almost operational again. David, another of our fabulous volunteers has been getting the loom ready to weave again. Moquette loom update – June 2023

Regular visitors to Calderdale industrial Museum will have noticed work being done on one of our star exhibits, the Moquette loom. One of our fabulous volunteers – Keith has been getting the loom ready to weave again. He has tied in the first warp, and is now pulling it through. This is a very fiddley job, especially as he has been doing much of the knotting

Welcome to Breastfeed – Calderdale award scheme

Calderdale Industrial Museum are delighted to join the “Welcome to Breastfeed – Calderdale” award scheme. The award scheme will raise awareness and recognise places across Calderdale where mums are welcomed and supported to breastfeed. The aim is to improve the health and well-being of local families.

Calderdale Industrial Museum are delighted to join the “Welcome to Breastfeed – Calderdale” award scheme. The award scheme will raise awareness and recognise places across Calderdale where mums are welcomed and supported to breastfeed. The aim is to improve the health and well-being of local families.Work on the museums Wrigley three wheel truck nears completion

The museum owns a Wrigley three-wheel light industrial truck donated as a restoration project by Bradshaw farmer Matthew Wilkinson in 2019.

The museum owns a Wrigley three-wheel light industrial truck donated as a restoration project by Bradshaw farmer Matthew Wilkinson in 2019.

It is a rare Wrigley model 332 made by Wessex industries in Poole, Dorset between July and August 1957, and is powered by a Villiers Mk 25 stationary engine which runs at a constant speed of about 2500 rpm. Road speed is changed through the gearbox, which should give speeds of 1, 2 and 6 mph. We think it was originally used by Marshall Stone Quarries in Southowram and later by Matthew Wilkinson to get to the pub !

It is now nearing the end of its restoration, and as can be seen from the photo of the truck when we got it, this was a major piece of work. Initially stripped down in one of our volunteers’ garage and then brought to the museum for restoration, many parts of the truck were missing or too corroded to use. The wheels and brakes were completely rebuilt, the chassis stripped and painted, the gearbox dismantled and reassembled, the engine stripped, given a bore, new piston and crankshaft regrind.

A difficulty has been sourcing and identifying the correct parts. An example is that we couldn’t obtain new brake springs and had to learn how to make springs from scratch.

The truck is now nearing completion. The engine is not yet running at full speed, the gearbox needs testing and panels are to be attached to the truck bed. After this it remains to tax it for road use. When complete the truck will be used to promote the museum at local events such as the Halifax Show.

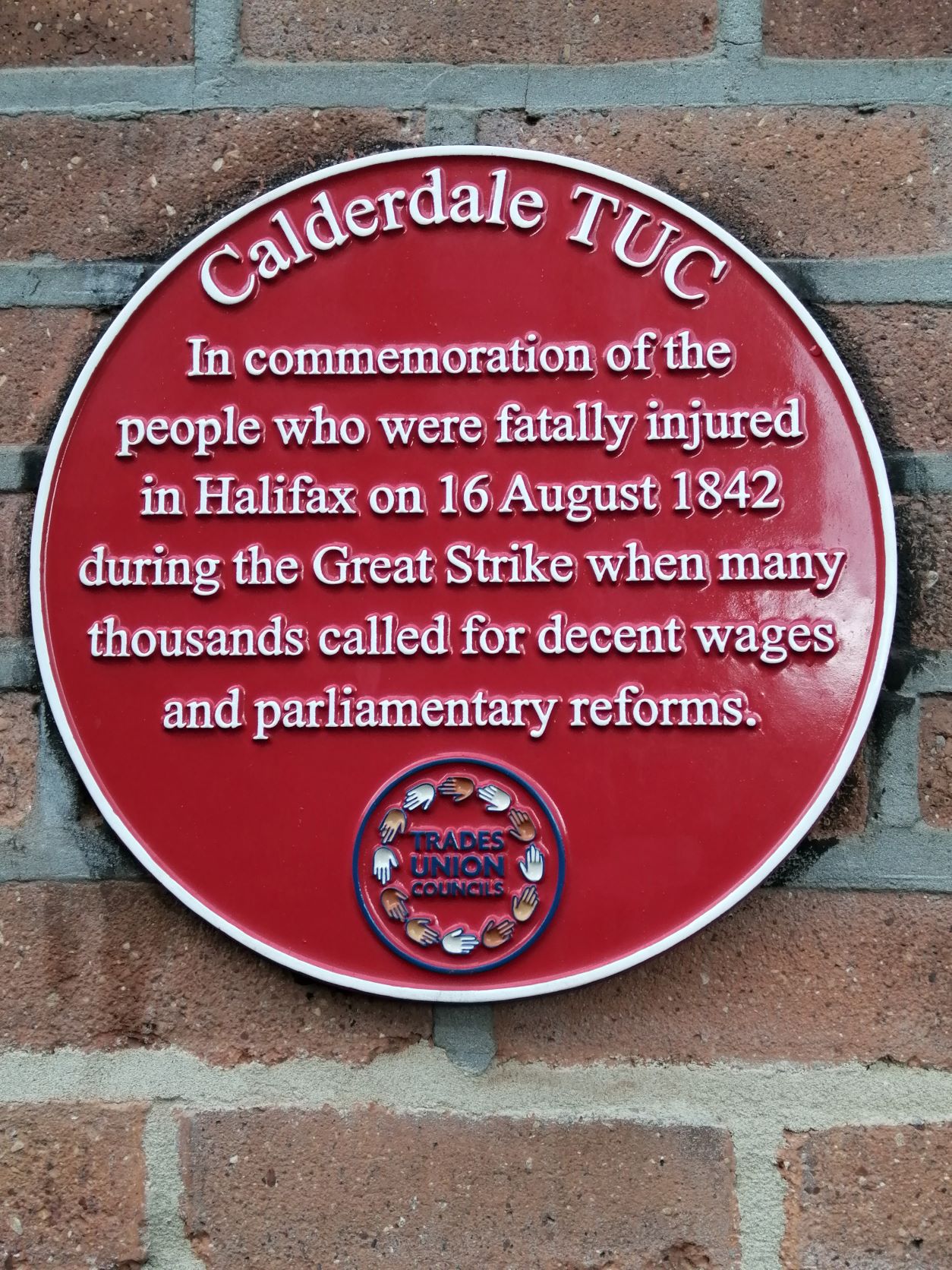

Rally of Resistance

It was interesting to see people gathered in the museum yard yesterday for the Calderdale Enough is Enough Rally of Resistance next to the Calderdale TUC plaque commemorating the Great Strike in Halifax in 1842.

It was interesting to see people gathered in the museum yard yesterday for the Calderdale Enough is Enough Rally of Resistance next to the Calderdale TUC plaque commemorating the Great Strike in Halifax in 1842.

Calderdale Industrial Museum is really pleased to have been listed as one of the Top 3 Places to visit in Halifax. You can read some of our reviews at https://threebestrated.co.uk/places-to-visit-in-halifax. We also have wonderful reviews on Trip Advisor. You can read these at https://www.tripadvisor.co.uk/Attraction_Review-g190786…

Calderdale Industrial Museum is really pleased to have been listed as one of the Top 3 Places to visit in Halifax. You can read some of our reviews at https://threebestrated.co.uk/places-to-visit-in-halifax. We also have wonderful reviews on Trip Advisor. You can read these at https://www.tripadvisor.co.uk/Attraction_Review-g190786…

Barbara the sheep !

Let’s welcome the newest member of the team at Calderdale Industrial Museum – Barbara the sheep ! You will find her peacefully grazing on our top floor in the Early Textiles display. Come and say hello to her. Many thanks to Janet Ashton and Anthony Griffiths for all their hard work in creating her. Anthony’s fantastic wood carvings showing the process of turning a fleece into a piece of cloth are also on display on the top floor.

Let’s welcome the newest member of the team at Calderdale Industrial Museum – Barbara the sheep ! You will find her peacefully grazing on our top floor in the Early Textiles display. Come and say hello to her. Many thanks to Janet Ashton and Anthony Griffiths for all their hard work in creating her. Anthony’s fantastic wood carvings showing the process of turning a fleece into a piece of cloth are also on display on the top floor.

Machine moving day !

Early Textiles now open

We are delighted to announce that the Early Textiles section of the museum is now open on the top floor of the museum. Visit our 18th century weavers cottage and learn how textiles were made before industrialisation.

We are delighted to announce that the Early Textiles section of the museum is now open on the top floor of the museum. Visit our 18th century weavers cottage and learn how textiles were made before industrialisation.

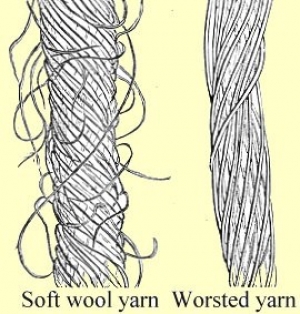

The exhibits illustrate the progress of the local textile industry during the period from the early to mid-eighteenth century when the local clothiers were rapidly introducing worsted goods into the area, through to the first adoption of the power loom around 1830. Many of the machines on display were originally invented for use in the cotton industry and were later able to be modified for use, first in making worsted goods and later for woollen production.

The typical eighteenth-century local weaver would not have had a farm, but depended almost entirely upon weaving, marketing his cloth through a factor or middleman rather than travelling to the cloth hall as his predecessors had done.

Wool textiles were probably being made in Calderdale soon after it was first settled. The earliest surviving evidence showed the town had a thriving woollen textile industry by 1150. By the 1470s the Parish of Halifax was paying tax on more cloths than any other town in the West and East Ridings of Yorkshire.  In the 1550s, Heptonstall had a woollen cloth hall and Halifax both a woollen hall and a linen hall, all three set up by the Lord of the Manor. A document of 1588 revealed that wool from the local sheep was considered too coarse to be used and was sold to ‘the men of Rochdale’; instead, most supplies were obtained from Lincolnshire, along with some of the finest wools from Craven. Worsted products were first introduced to this area in the late seventeenth century from East Anglia, augmenting existing woollen trade here and was well established by the 1720s. By the late eighteenth century, cotton spinning was another new textile process, introduced into the upper parts of the Calder and Ryburn valleys to take advantage of the availability of water power for the building of new mills. Water power was introduced for the spinning of worsted yarn in the Calder valley during the 1790s. At the start of the nineteenth century, a burgeoning carpet industry began to use jute as backing material for carpets. In 1830, Benjamin Outram succeeded in spinning and weaving alpaca fibres at his mill near Greetland, though with little financial reward. In the middle of the nineteenth century, silk began to be used in some worsted fabrics, prompting the establishment of several silk spinning mills near Hebden Bridge, Brighouse and also the Ryburn valley. During the twentieth century, numerous synthetic yarns were developed and began to be combined with, or replaced natural fibres.

In the 1550s, Heptonstall had a woollen cloth hall and Halifax both a woollen hall and a linen hall, all three set up by the Lord of the Manor. A document of 1588 revealed that wool from the local sheep was considered too coarse to be used and was sold to ‘the men of Rochdale’; instead, most supplies were obtained from Lincolnshire, along with some of the finest wools from Craven. Worsted products were first introduced to this area in the late seventeenth century from East Anglia, augmenting existing woollen trade here and was well established by the 1720s. By the late eighteenth century, cotton spinning was another new textile process, introduced into the upper parts of the Calder and Ryburn valleys to take advantage of the availability of water power for the building of new mills. Water power was introduced for the spinning of worsted yarn in the Calder valley during the 1790s. At the start of the nineteenth century, a burgeoning carpet industry began to use jute as backing material for carpets. In 1830, Benjamin Outram succeeded in spinning and weaving alpaca fibres at his mill near Greetland, though with little financial reward. In the middle of the nineteenth century, silk began to be used in some worsted fabrics, prompting the establishment of several silk spinning mills near Hebden Bridge, Brighouse and also the Ryburn valley. During the twentieth century, numerous synthetic yarns were developed and began to be combined with, or replaced natural fibres.

Dementia Awareness Training for Museum Volunteers

Moquette items for sale in the museum shop

We are very excited to launch a new range of products in our shop from Shed No. 2. The company make beautiful items from moquette fabric. The fabric will be very familiar to anyone who has ever travelled on a train, tube train or bus, as it is the hard wearing colourful fabric used for seating. It also makes the wonderful cushions, pencil cases, glasses cases and purse that are now on sale in our shop.

We are very excited to launch a new range of products in our shop from Shed No. 2. The company make beautiful items from moquette fabric. The fabric will be very familiar to anyone who has ever travelled on a train, tube train or bus, as it is the hard wearing colourful fabric used for seating. It also makes the wonderful cushions, pencil cases, glasses cases and purse that are now on sale in our shop.

Privacy Policy Cookie Policy Accessibility Terms ![]() Like us on Facebook

Like us on Facebook ![]() Twitter and Instagram

Twitter and Instagram